APPLICATION: To provide linear speed of the thread/ cloth getting wound on a roller of Warping Machines.

INDUSTRY: Textile, Rubber Wire, Paper, Plastic Processing Industry

MODEL: LCLS 262- AO10

DETAILS:

In warping machines threads / cloth / is getting wound on a roller. As thread gets accumulated on shaft, diameter of the roller increase. This increases the linear speed of the thread, even though RPM remains same. ( As the diameter increase, thread pulled per rotation increases). Our controller offers solution to keep the linear speed of the thread constant.

SOLUTION:

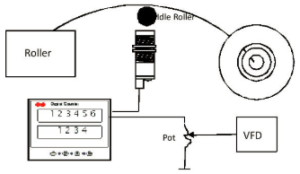

Electronic Switches offers solution for above problem . Our system consists of a controller. In winding application there is a idle roller and material passes over the idle roller. Inductive proximity switch is to be mounted to sense the rotation of roller. RPM increases as material is getting build up on a winding roller.. RPM sensed through Inductive proximity, linear speed will be displayed on a controller. Diameter of roller is to be entered in the controller. As per the diameter of the roller, display will show length of the web in meters.Winding roller speed is control through VFD. Speed of the motor can be vary by applying 0 – 10 V DC through VFD. As per the required linear speed the unit will supply 0-10 V DC to VFD so as to keep the linear speed constant.