This is where you should answer the most common questions prospective customers might have. It’s a good idea to cover things like your return policy, product warranty info, shipping and returns, etc. Check out the examples below.

We do not take back any product unless the product doesn’t work as per suggested by us OR doesn’t fulfill your application. For more information please mail us on given email ID on the website.

Yes, we’ll ship your package anywhere that can accept deliveries.

Of course! Our friendly and knowledgeable customer services reps are available to answer your questions on weekdays 9.00 am to 6.00 pm.

We offer 1 year warranty for all our standard products against any manufacturing defect. For any other customized product, the warranty clause is not applicable. Warranty period differs depending on products.

The NAMUR type sensor is intrinsically safe proximity switches designed to work in the hazardous areas. The working voltage & current levels of these switches are restricted to safe values as per standards. Also, It is non-amplified sensor that supplies two different signal levels depending upon switch state. These signal levels are low-level current. A logic interface circuit, controller, PLC, DCS, or intrinsically safe (IS) barrier is needed to read these current levels.

Potential Free Contacts this term is used for Relay Contacts. When Relay Contacts are not connected in any circuit, it does not have any voltage or potential at the contacts. Hence Relay Contacts (NC – C – NO) without any connections are known as Potential Free Contacts.

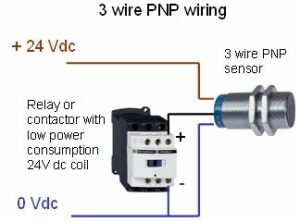

Two specific types of 3 wire sensors are available; PNP and NPN. The difference is a result of the internal circuit design and type of transistors used. A key point to observe is that PNP and NPN has nothing to do with whether the sensor is normally open (N/O) or normally closed (N/C), i.e. a PNP sensor may be either N/O or N/C as can an NPN be either N/O or N/C.

Traditional relay type control circuit;

IP rating is also known as Ingress Protection or International Protection ratings which are defined to the international standard of EN 60529.These standards are used to define the levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies such as dirt and water.

The rating consists of the letters IP followed by 2 digits, the first digit stands for the level of protection that the enclosure provides against solid bodies, the second digit describes the degree of protection of the equipment inside the enclosure against water.

IP65 = First Digit – Solids

IP65 = Second Digit – Liquids

Below is an easy to follow chart to help you decide which IP rating / IP Codes you may require for your electrical enclosure, Rainford manufacturers IP rated electrical enclosures including IP54, IP65 up to IP66.

| IP Rating | First Digit – SOLIDS | Second Digit – LIQUIDS |

| IP54 | Protected from limited dust ingress | Protected from water spray from any direction, limited ingress protection |

| IP55 | Protected from limited dust ingress | Protected from low pressure water jets from any direction, limited ingress protection |

| IP56 | Protected from limited dust ingress | Protected from high pressure water jets from any direction, limited ingress protection |

An infrared sensor is an electronic device that emits in order to sense some aspects of the surroundings. An IR sensor can measure the heat of an object as well as detects the motion. These types of sensors measures only infrared radiation, rather than emitting it that is called as a passive IR sensor.

Proximity Sensor includes all sensors that perform non-contact detection in comparison to sensors, such as limit switches, that detect objects by physically contacting them. Proximity Sensors convert information on the movement or presence of an object into an electrical signal. There are three types of detection systems that do this conversion: systems that use the eddy currents that are generated in metallic sensing objects by electromagnetic induction, systems that detect changes in electrical capacity when approaching the sensing object, and systems that use magnets and reed switches.

Inductive Proximity Sensors detect magnetic loss due to eddy currents that are generated on a conductive surface by an external magnetic field. An AC magnetic field is generated on the detection coil, and changes in the impedance due to eddy currents generated on a metallic object are detected.

There are also Pulse-response Sensors, which generate an eddy current in pulses and detect the time change in the eddy current with the voltage induced in the coil.

(Qualitative Explanation)

The sensing object and Sensor form what appears to be a transformer-like relationship.

The transformer-like coupling condition is replaced by impedance changes due to eddy-current losses.

The impedance changes can be viewed as changes in the resistance that is inserted in series with the sensing object.

Detection Principle of Capacitive Proximity Sensors

Capacitive Proximity Sensors detect changes in the capacitance between the sensing object and the Sensor. The amount of capacitance varies depending on the size and distance of the sensing object. An ordinary Capacitive Proximity Sensor is similar to a capacitor with two parallel plates, where the capacity of the two plates is detected. One of the plates is the object being measured (with an imaginary ground), and the other is the Sensor’s sensing surface. The changes in the capacity generated between these two poles are detected.

The objects that can be detected depend on their dielectric constant, but they include resin and water in addition to metals.

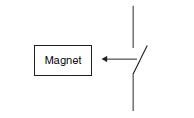

Detection Principle of Magnetic Proximity Sensors

The reed end of the switch is operated by a magnet. When the reed switch is turned ON, the Sensor is turned ON.

RS-485 devices can be connected to a computer and multi-dropped at various locations in a network style configuration. Devices can be up to 4000 feet (1220 meters) feet away before a repeater is needed, and up to 32 nodes (devices) can be connected. More nodes can be connected using repeaters, up to the addressability limit (usually 256) of the devices used.

Yes! Our products accepts both the inputs from PLC. Our product can be used as slave to display any vales transferred from PLC, it may be numeric as well as alpha-numeric both.

Copyright 2023 © All rights Reserved. Design by Rathinfotech